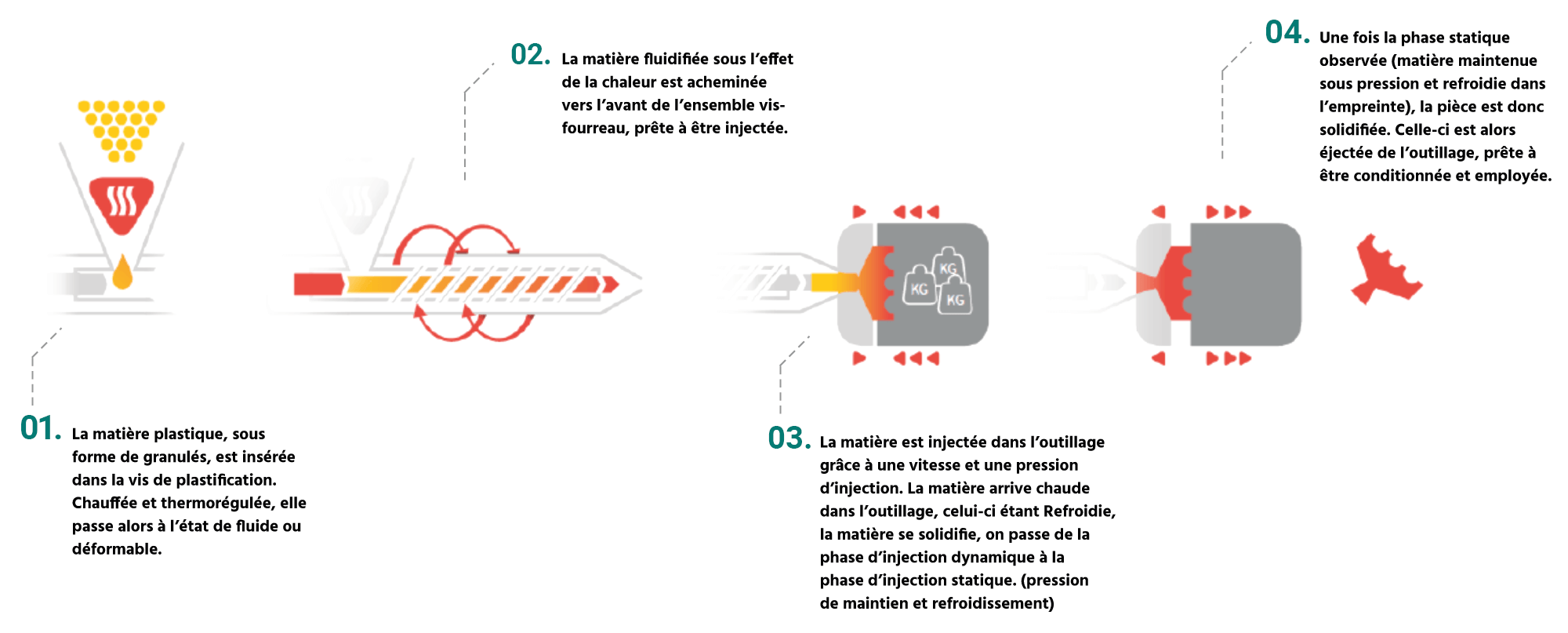

The operation of an injection moulding machine to produce parts is relatively simple. Homogeneous plastic granules are poured into a drying oven to remove residual humidity and then sucked up by a hoover. This material is then softened in the screw and barrel assembly by being heated to 200°C – 400°C by the combined action of the friction of the screw and the heating collars (the injection temperature being variable according to the materials processed). The malleable material is pushed towards the nozzle and then injected into the mould by the injection cylinder. The injection pressure can reach 2,500 bar. The material is distributed evenly in the tool cavity to take its final shape. The part is then cooled in a few seconds to between 50°C and 80°C (or even more for certain technical materials, e.g., PEEK) to solidify it. The press opens the tooling and any drawers, the part is ejected by the ejection battery and falls into a tray or is picked up by a robot manipulator. The press closes and the cycle starts again.

The plastic material, in granular form, is inserted into the plasticising screw.

Heated and thermoregulated, it is then transformed into a fluid or deformable state.