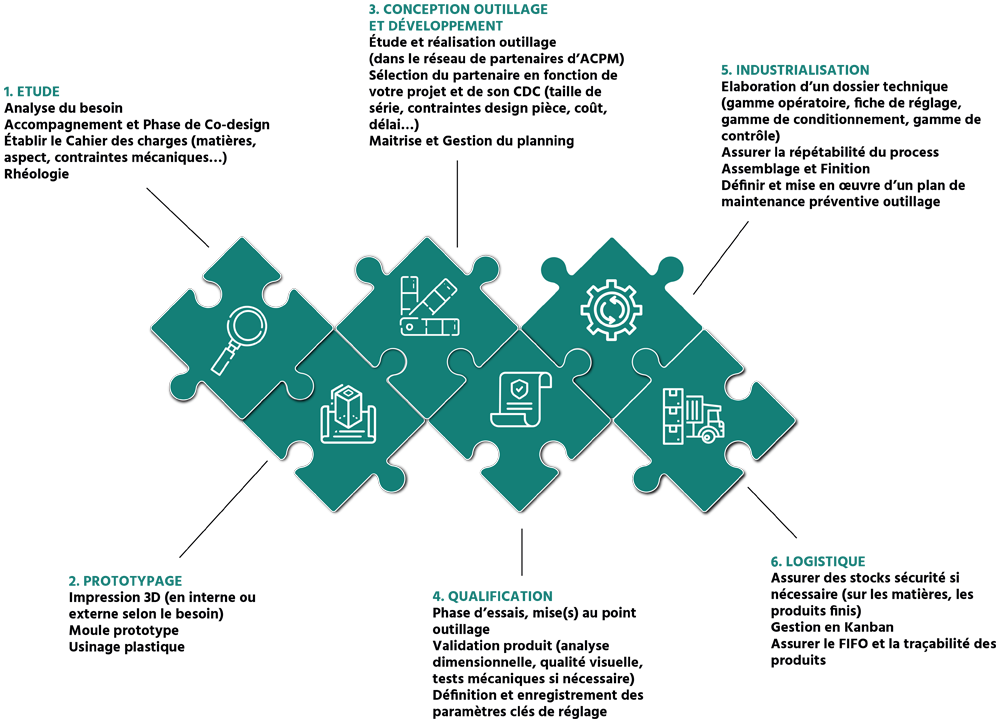

OUR SUPPORT

From reflection to implementation.

Through the circular economy, confidentiality and transparency, the ACPM team will ensure that your project is managed in full accordance with your expectations.

1 STUDY

Analysis of the need

Co-design phase and support

Establishing the specifications (materials, appearance, mechanical constraints, etc.)

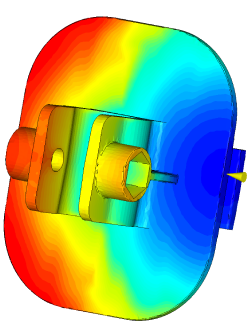

Rheology

2 PROTOTYPING

3D printing

(internally or externally depending on the need)

Prototype mould

Plastic machining

3 TOOLING DESIGN AND DEVELOPMENT

Tooling design and development (within ACPM’s partner network)

Selection of the partner according to your project and its specifications (series size, part design constraints, cost, deadline).

Control and management of the schedule

4 QUALIFICATION

Trial phase, tooling development(s)

Product validation (dimensional analysis, visual quality, mechanical tests if necessary)

Definition and recording of key setting parameters

5 INDUSTRIALIZATION

Drawing up a technical file (operating range, adjustment sheet, packaging range, control).

Ensure process repeatability

Assembly and Finishing

Define and implement a preventive maintenance plan for tools

6 LOGISTICS

Ensure safety stocks if necessary (on materials, finished products)

Kanban management

Ensure FIFO and product traceability